Learn how to streamline business processes with our expert guide. Discover actionable strategies for workflow automation and improved productivity.

August 4, 2025 (6mo ago) — last updated January 6, 2026 (1mo ago)

How to Streamline Business Processes for Peak Efficiency

Learn how to streamline business processes with our expert guide. Discover actionable strategies for workflow automation and improved productivity.

← Back to blog

If you want to get your business operations running smoothly, it really comes down to four key areas: taking a hard look at how you do things now, using the right technology smartly, giving your team the power to act, and never stopping the improvement cycle. When your operations are inefficient, they become a quiet drain on your budget, a source of frustration for your team, and a real handicap in the market. Fixing this isn't just a minor tweak; it's fundamental for growth.

Why Streamlining Is No Longer Optional

Inefficient processes are more than just small annoyances—they're a major drag on your company's potential. Think about all the time wasted on repetitive data entry, navigating confusing approval chains, or just trying to find the right information. Each one of those moments is a hidden cost that adds up, day after day. This isn't just about lost hours; it's about the compounding effect on your budget, your team's morale, and your ability to come up with the next big idea.

When workflows are clunky and ill-defined, people get disengaged. The risk of making a costly mistake goes way up. In a market where every advantage counts, the speed and quality of your operations have a direct impact on customer happiness and, ultimately, your bottom line. Tackling these operational bottlenecks has moved from a "nice-to-have" project to a critical move for survival and growth.

The Tangible Costs of Inefficiency

This operational drag shows up in a few different ways, and each one has a real-world price tag. The most obvious is wasted time, which is a direct hit to your labor costs. But what's less obvious, and arguably more damaging, are the opportunity costs. What strategic projects could your team be spearheading if they weren't stuck doing manual, repetitive tasks?

"A survey by The Alternative Board found that 72% of small business owners** feel overwhelmed by their responsibilities, a feeling often tied to chaotic, unrefined processes."

Being in a constant state of overwhelm kills creativity and strategic thinking. A great starting point for gaining clarity is to understand the foundational principles and proven ways to streamline business processes. By turning vague frustrations into a concrete plan, you can start reclaiming those valuable resources and point them toward activities that actually grow the business.

The Power of Smart Automation

Technology, especially automation, is a game-changer here. The numbers don't lie. Over 90% of workers say they're more productive after their company brought in automation. On top of that, businesses that make the investment see operating costs drop by an average of 22%.

But here’s the catch: technology isn't a magic wand. Roughly 70% of digital transformation projects don't hit their targets. This is a crucial lesson—you can't just buy software and expect miracles. You need a smart strategy behind it.

Optimizing how your business runs delivers a powerful ripple effect of benefits across the entire organization. We've compiled a quick summary of the key advantages you can expect.

Key Benefits of Streamlining Business Processes

A summary of the primary advantages organizations gain by optimizing their operational workflows.

| Benefit Area | Impact on Business |

|---|---|

| Improved Productivity | Frees up employees to concentrate on high-value work, leading to faster project completion. |

| Enhanced Cost Efficiency | Directly cuts operational expenses by optimizing resource use and eliminating wasted effort. |

| Better Communication | Creates clear, standard procedures so everyone knows their role, reducing confusion. |

| Greater Customer Satisfaction | Enables faster, more reliable service, which builds customer loyalty and positive word-of-mouth. |

Ultimately, these benefits work together. Better productivity leads to cost savings, which can be reinvested. Clearer communication improves team cohesion and service quality, directly impacting customer happiness. It's a cycle of positive reinforcement that fuels sustainable growth.

How to Map and Analyze Your Current Workflows

Before you can fix a broken process, you have to understand it inside and out. It’s impossible to improve a workflow you can’t see. This first phase isn't about jumping to solutions; it's about pure investigation. Your job is to turn those vague, nagging frustrations into a concrete map that shows how work actually gets done.

Think of yourself as a detective inside your own company. You need to follow a process from start to finish, documenting every handoff, delay, and workaround. This creates the baseline you’ll need to make smart, data-driven improvements later on.

Start With a Single, High-Impact Process

Trying to map every workflow at once is a surefire way to get overwhelmed and give up. It just doesn't work. Instead, pick one specific process to put under the microscope first.

A great candidate is a workflow that’s either performed constantly, a frequent source of complaints, or something that directly touches your customers. For example, a new client onboarding process is a perfect place to start. It usually involves multiple people and departments, making it a prime spot for hidden bottlenecks that can sour a new client relationship from day one.

Other good starting points often include:

- Invoice processing and payment: A classic area often bogged down by manual approvals and data entry.

- Content creation and publication: This typically requires a complex dance between writers, designers, and marketers.

- Hiring and employee onboarding: A critical process that sets the tone for an employee's entire journey with your company.

By focusing on one area, you make the task manageable and, more importantly, create a repeatable blueprint you can use for other workflows down the road.

Gather Your Process Stakeholders

Here's a hard truth: you can't map a process accurately from your desk. The most valuable information comes directly from the people doing the work day in and day out. They’re the ones who know the workarounds, the real frustrations, and the "unwritten rules" that never make it into a formal manual.

Get everyone involved in the process into a room for a workshop or a series of quick interviews. For client onboarding, this means talking to the salesperson who closes the deal, the project manager who kicks things off, and the finance person who sends the first invoice. Everyone has a piece of the puzzle.

The goal here is to create a space for honest feedback. Stress that this isn't about pointing fingers. It's about working together to make everyone's jobs easier and more effective.

When people feel heard and understand that their expertise is essential, you build buy-in right from the start.

Visualize Every Step of the Workflow

With your team assembled, it's time to make the process visible. The simple act of mapping it out on a whiteboard or with a digital tool forces clarity and immediately exposes gaps you might have missed. Use a large whiteboard, a wall with sticky notes, or a flowcharting app—whatever works for your team.

Let's go back to our client onboarding example. You'd begin the map right at the moment a contract is signed.

Actionable Mapping Questions

- What's the very first thing that happens? (e.g., "The salesperson marks the deal as 'won' in our CRM.")

- Then what? Who takes the next step? (e.g., "An automatic alert goes to the finance and project management teams.")

- What information or files are needed for that step? (e.g., "Finance needs the signed contract to create the invoice.")

- How long does this step usually take? (e.g., "It can take up to 48 hours for the project manager to schedule a kickoff call.")

Keep asking these questions until you've traced the entire process from beginning to end. This detailed approach uncovers the reality of your workflow, not the idealized version that might be sitting in an outdated handbook.

Identify and Quantify the Inefficiencies

Once your map is complete, the bottlenecks will practically jump off the page. You’ll see where work piles up, where approvals cause frustrating delays, and where people are entering the same data into three different systems.

Now it's time to attach numbers to these problems. Go back through your map and label the trouble spots with hard data.

| Problem Type | Example Metric | Onboarding Scenario |

|---|---|---|

| Delays | Average wait time | The 48-hour lag between contract signing and the kickoff call. |

| Redundancy | Number of manual data entry points | Sales, finance, and project management all re-entering client data into separate systems. |

| Errors | Rate of incorrect information | A 5% error rate in invoices from manual creation, forcing rework. |

| Lack of Clarity | Number of clarification emails | The project team sending an average of three emails to sales for project details. |

This quantification is what gives your initiative teeth. It transforms a vague complaint like "invoicing takes too long" into a powerful data point: "Manual invoice creation and approval adds an average of three business days to our payment cycle." That’s the kind of concrete evidence that builds an undeniable case for change.

A crucial part of this analysis is implementing effective accounting workflow management to boost efficiency and cut down on costly financial errors. By mapping these financial touchpoints, you build a solid foundation for targeted, meaningful improvements.

How to Pinpoint and Prioritize What to Improve First

So, you've mapped your workflows. Now you’re probably looking at a mountain of potential fixes and wondering, "Where on earth do I start?" It's a common feeling. If you try to tackle everything at once, you'll just create chaos and burn out your team.

The trick is to shift from just spotting problems to strategically picking your battles. You need a data-backed plan, not just a gut feeling about what’s broken. This is where you put on your strategist hat to figure out which changes will give you the most bang for your buck and build momentum for the long haul.

Use the Impact vs. Effort Matrix

One of the best tools I've found for this is the Impact vs. Effort matrix. It’s a simple concept but incredibly powerful for getting your priorities straight. You just draw a four-quadrant grid: "Impact" goes up the side (low to high), and "Effort" runs along the bottom (low to high).

Then, you start placing each process issue you’ve identified onto the grid. This exercise forces you to get real about the potential payoff of a fix versus the time, money, and people it will take to get it done.

It quickly sorts your opportunities into four clear buckets:

- High Impact, Low Effort (Quick Wins): These are your gold mines. Go after them first. They deliver noticeable results fast without draining your resources, which is perfect for getting everyone on board. A classic example is creating a standard email template for new client inquiries to slash response times.

- High Impact, High Effort (Major Projects): Think of these as your game-changers. They require serious planning and investment—like implementing a new CRM—but the payoff can be massive. You'll need a solid business case to get these approved.

- Low Impact, Low Effort (Fill-ins): These are the small, "nice-to-have" tweaks. Do them when you have downtime, but don't let them distract from bigger goals. Reorganizing a shared drive is a perfect example.

- Low Impact, High Effort (Thankless Tasks): Avoid these like the plague. They gobble up resources for almost no gain and can completely derail your progress.

This matrix is a cornerstone of smart task management. If you're looking for more strategies like this, our guide on prioritizing tasks at work is a great next step.

Calculate the Potential Return on Investment

For those major projects, a simple matrix isn't enough. You need to crunch the numbers and calculate the potential return on investment (ROI). And I don't just mean money—I mean the total value the change brings to the business.

First, tally up the costs: software licenses, training hours, maybe some consulting fees. Then, start quantifying the benefits. It's often easier than it sounds.

| Benefit Category | How to Quantify It | Example Scenario (Automating Invoicing) |

|---|---|---|

| Time Savings | Calculate hours saved per week/month and multiply by the employee's hourly rate. | Saves 5 hours/week for an employee earning $30/hour = $600/month in recovered time. |

| Cost Reduction | Identify direct cost savings from eliminating tools, materials, or errors. | Reduces printing and mailing costs by $100/month. |

| Quality Gains | Estimate the financial impact of reduced errors, rework, or customer complaints. | Cuts invoice error rate by 90%, avoiding $250/month in correction costs. |

When you can add up these gains, you get a powerful number to bring to leadership. "This $1,000 software will deliver over $950 in value every single month" is a much stronger pitch than a vague promise of "better efficiency."

Build a Compelling Business Case

With your analysis complete, the final step is to package it all into a clear, persuasive business case, especially for those high-effort projects. This document needs to tell a simple story: here's the problem, here's our solution, here's what it will cost, and here's the ROI.

A strong business case connects your process improvement goals directly to the company's broader strategic objectives, like increasing profitability or improving customer retention.

When you can show that fixing a process supports a bigger company goal, you're far more likely to get the green light. The data backs this up. Organizations that embrace automation have seen a 6.7% increase in customer engagement. Better yet, over 90% of IT professionals report that automation frees up their colleagues to focus on more valuable, strategic work. Tying your project to these kinds of proven outcomes makes your case undeniable.

Choosing and Implementing the Right Automation Tools

Once you’ve mapped out your workflows and pinpointed the bottlenecks, it’s time to bring in the right technology. This is where you can truly learn how to streamline business processes, turning those identified pain points into real, everyday efficiencies. This isn’t about just grabbing the latest shiny object; it’s about making a smart, practical choice that gives your team the right tools for the job.

The goal is to find a solution that directly solves the problems you've uncovered. Whether you’re a small shop needing a simple task manager or a larger company exploring a full-blown automation platform, the approach is the same: match the tool to the task, not the other way around.

Differentiating Automation Technologies

"Automation" is a broad term, covering a whole spectrum of tools. Getting familiar with the main categories is the first step to making a good decision. The right choice really hinges on how complex your processes are.

- Simple Workflow Apps: These are fantastic for straightforward tasks and smaller teams. Think of project management tools with basic "if this, then that" rules for sending notifications, creating tasks, or chasing up approvals. They’re often low-cost, easy to set up, and deliver some quick wins.

- Robotic Process Automation (RPA): RPA is all about teaching a software "bot" to mimic human actions on a computer. It can log into apps, copy and paste data between systems, fill out forms, and move files—all without human intervention. This is perfect for high-volume, rules-driven work like processing invoices or generating standard reports.

- Intelligent Process Automation (IPA): Take RPA and add a layer of artificial intelligence and machine learning, and you get IPA. This advanced tech can handle more nuanced tasks that involve unstructured data (like reading an email) or require a bit of judgment.

If you want to go deeper on this, our guide on what is workflow automation is a great resource for understanding how these concepts apply in the real world.

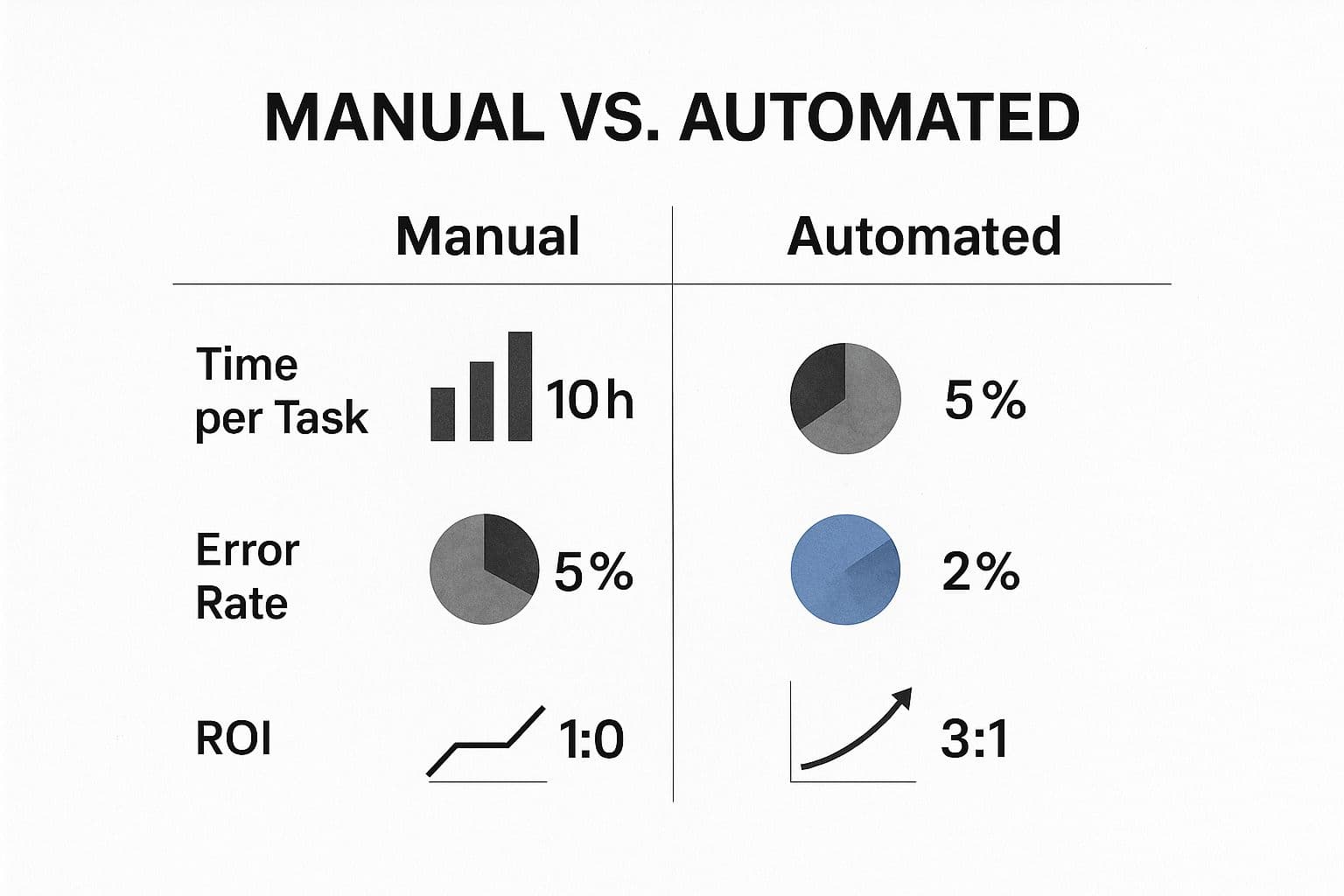

The shift from manual to automated work isn't just a minor tweak—it's a game-changer. The results speak for themselves, with major gains in speed, accuracy, and overall value.

As you can see, automation doesn't just cut task time—it slashes errors and delivers a powerful return on your investment.

To help you navigate the options, it's useful to see how different automation technologies stack up. Each has its own strengths and is suited for different kinds of business challenges.

Comparing Automation Technologies for Business Processes

| Technology Type | Best For | Example Use Case | Complexity Level |

|---|---|---|---|

| Workflow Automation | Linear, multi-step processes involving people and systems. | Onboarding a new employee, processing a vacation request. | Low to Medium |

| Robotic Process Automation (RPA) | Repetitive, rules-based tasks within digital systems. | Extracting data from an invoice and entering it into an ERP. | Medium |

| Intelligent Process Automation (IPA) | Complex processes needing some cognitive ability. | Analyzing customer support emails to route them to the right department. | High |

| No-Code/Low-Code Platforms | Empowering non-technical users to build their own simple apps. | Creating a custom tool for tracking project-specific inventory. | Low |

Choosing the right technology from this list depends entirely on the specific problem you're trying to solve, your team's technical skills, and your budget.

Making an Informed Tool Selection

Picking the right platform goes beyond a simple feature comparison. You need to really think about how a tool will fit into your day-to-day operations and whether your team can actually use it. After all, a powerful tool nobody uses is just expensive shelfware.

Start by making a shortlist of your must-haves. Ask yourself these questions:

- Integration Capability: How well does it play with the software you already rely on, like your CRM or accounting system? You need something that connects smoothly to avoid creating more work.

- Scalability: Will this solution grow with you? A tool that's perfect for a team of five might buckle under the pressure of fifty. Think a year or two down the road.

- Ease of Use: Honestly, how hard is it to learn? A platform with a clean, intuitive interface like Fluidwave will get adopted much faster than a clunky system that requires a Ph.D. to operate.

- Support and Training: What happens when you get stuck? Look for vendors that offer solid documentation, responsive support, and training resources to get your team up and running.

The right automation tool should feel like a natural extension of your team. It’s there to simplify things and free up brainpower, not add another layer of complexity to everyone’s day.

Once you’ve narrowed it down, run a small pilot project. Pick that one high-impact, low-effort process you identified earlier and test the tool in the real world. This will tell you everything you need to know before you commit to a company-wide rollout.

Building a Culture of Continuous Improvement

Let's be honest. The biggest wins in process improvement don't come from a single, massive overhaul. The real victory is when optimization stops being a "project" and becomes part of your company's DNA. It’s about creating a place where every person on your team is actively looking for smarter ways to work.

This is a fundamental shift in mindset, moving away from "this is just how we do things" to "how can we make this better?" When you achieve that, you've unlocked genuine, long-term efficiency and agility. It's no longer a top-down mandate; it's a living, breathing part of your operations.

Establish Meaningful Performance Metrics

You can't fix what you can't see. Before you start tweaking workflows, you have to define what success actually looks like in concrete, measurable terms. These Key Performance Indicators (KPIs) are your guiding light, telling you if your changes are actually moving the needle.

Forget vague goals like "increase efficiency." Get specific. Tie your metrics directly to the processes you're refining.

- Lead Time Reduction: How long does it take from a customer's first ask to the final delivery? A tangible goal might be cutting project kickoff time from 48 hours down to 24 hours.

- Error Rate Decrease: What percentage of your work needs to be redone? A powerful KPI is driving down invoice errors from 5% to under 1%.

- Process Cycle Time: How much hands-on time does a task require? Try to trim something like your content approval cycle from three days to just one.

These aren't just numbers on a dashboard. They ground your conversations in reality, moving discussions from subjective feelings to data-backed decisions. That's how you make smart adjustments.

Introduce a Framework for Iteration

A culture of improvement needs a simple, repeatable system that everyone can latch onto. From my experience, one of the most effective is the Plan-Do-Check-Act (PDCA) cycle. It’s a straightforward, four-stage loop for testing and rolling out changes.

The real power of PDCA is its simplicity. It gives everyone a shared language and a structured way to tackle problems, so teams don't get stuck just talking about ideas without ever taking action.

Here’s how you can put it to work:

- Plan: Pinpoint an opportunity and form a hypothesis. For example, "We believe a standardized client intake form will cut down on kickoff delays."

- Do: Roll out the change on a small scale. Don't disrupt everyone; just test the new form with your next couple of clients.

- Check: Dig into the results and measure against your KPIs. Did the form actually speed things up? By how much?

- Act: If it worked, make it the new standard. If not, figure out what went wrong, learn from it, and start the cycle over with a new plan.

This iterative approach encourages experimentation. It makes it safe to learn from both wins and losses, ensuring improvements are constant and build on each other.

Create Powerful Feedback Loops

The people on the front lines know the real story. They live with the process every day and see its flaws up close. Your team is a goldmine of practical insights, but you’ll never tap into it without creating clear channels for them to share what they know.

This is about much more than a suggestion box collecting dust in the corner. It means actively soliciting and, most importantly, acting on employee feedback.

| Feedback Method | How It Works |

|---|---|

| Regular Process Huddles | Quick, weekly meetings focused on one specific workflow to talk openly about what’s working and what’s not. |

| Digital Idea Boards | Use a tool like Fluidwave where anyone can post an idea for improvement and the team can vote on it. |

| "Shadowing" Sessions | Have a manager spend a few hours observing a team member's workflow to see the bottlenecks firsthand. |

When your team sees their ideas being taken seriously and put into action, they become more invested and proactive. This creates an incredible virtuous cycle: more ideas are shared, more improvements are made, and your entire organization gets stronger. For more strategies on this, check out our guide to improve operational efficiency.

Ultimately, streamlining processes is a key part of building a culture of excellence. It’s about fostering an environment where improvement is a shared responsibility and a source of pride. When you make optimization a daily habit, you build an organization that isn't just efficient—it's agile and ready for whatever comes next.

Common Questions About Streamlining Business Processes

Taking the first steps toward process improvement always kicks up a few questions. It’s one thing to talk about theory, but putting it into practice is where the real work begins. To help you move forward with confidence, I've answered some of the most common questions I hear from teams just starting out.

Think of this as a field guide for clearing the practical hurdles you’ll face. The goal here is direct, honest advice you can use right away.

Where Should a Small Business Start?

For a small business, the absolute best place to start is with whatever process is causing the most headaches. Don't try to fix everything at once—that's a recipe for burnout. Instead, pick one high-impact area and focus all your energy there.

Usually, this is a process like customer invoicing, managing inventory, or even onboarding a new client. Find the workflow that feels clunky and time-consuming. Get your team in a room with a whiteboard (or a simple digital tool) and map it out, step by step. Critically, you need to ask the people doing the work: "What's the most frustrating part of this for you?"

You'll almost always find some quick wins. It might be as simple as creating a standard email template for follow-ups, using a shared digital checklist so nothing gets missed, or adopting a basic project management app to see who is doing what.

Getting a tangible result early on is huge. It builds the momentum you need and proves to everyone on the team that this effort is well worth their time.

How Do I Get My Team on Board?

Getting your team to embrace change is essential, and it really comes down to communication and involvement. Start by explaining the why. Don't just talk about efficiency; frame it in terms of benefits that matter to them—less boring data entry, fewer mistakes to clean up, and more time for work they actually enjoy.

Even better, pull them into the process from day one. Ask for their input on what’s not working and how they would fix it. People will always support a solution they helped build.

When you introduce a new tool or system, make sure the training is solid and ongoing support is readily available. It’s also important to position automation as a "digital assistant" that handles the repetitive stuff, not as something meant to replace people. And finally, celebrate the wins, big and small, and give a shout-out to the people who are leaning in and helping make the change a success.

Streamlining vs. Business Process Reengineering

I often see these two terms used interchangeably, but they represent very different philosophies. Understanding the distinction is key.

- Process Streamlining is all about incremental improvement. You take an existing workflow, find the bottlenecks and wasteful steps, and make it better, faster, or more reliable. Think of it as fine-tuning what you already have.

- Business Process Reengineering (BPR) is far more radical. It’s about starting with a blank slate and completely rethinking a core process. Instead of asking, "How can we improve this task?" BPR asks, "Why are we even doing this in the first place?"

In a nutshell, streamlining is evolutionary, while BPR is revolutionary. For most businesses, especially smaller ones, starting with streamlining is the most practical and sustainable path to getting results.

Ready to stop juggling tasks and start delegating them intelligently? Fluidwave combines powerful task management with on-demand virtual assistants to help you reclaim your time. Create, automate, and delegate your tasks with Fluidwave today.

Focus on What Matters.

Experience lightning-fast task management with AI-powered workflows. Our automation helps busy professionals save 4+ hours weekly.