Discover proven strategies to improve operational efficiency and streamline your business for better productivity and sustainable growth.

June 12, 2025 (7mo ago) — last updated January 7, 2026 (26d ago)

Boost Growth: Tips to Improve Operational Efficiency

Discover proven strategies to improve operational efficiency and streamline your business for better productivity and sustainable growth.

← Back to blog

Unlocking Peak Performance: A Guide to Operational Efficiency

In today's competitive business landscape, operational efficiency is paramount to success. This listicle provides 10 actionable strategies to improve operational efficiency, streamline your workflows, and boost your bottom line. Whether you're a seasoned executive or a startup founder, these insights will help you optimize resource allocation and achieve sustainable growth. Learn how to eliminate waste, automate processes, and empower your team to reach peak performance. Discover how Fluidwave can further enhance these strategies through its AI-driven task management and virtual assistant capabilities.

This guide explores key areas crucial for improving operational efficiency:

- Process Optimization:** Lean Manufacturing, Six Sigma, and Workflow Standardization.

- Technology Integration: Process Automation, Robotics, ERP implementation, and Data Analytics.

- Strategic Management: Supply Chain Optimization, Agile and DevOps, Continuous Improvement, and Outsourcing/Offshoring.

- Performance Enhancement: Performance Management and KPI Optimization.

By implementing these strategies, you can achieve significant improvements in:

- Reduced Costs: Eliminate waste and optimize resource utilization.

- Increased Productivity: Streamline workflows and automate repetitive tasks.

- Improved Quality: Implement robust quality control measures and minimize errors.

- Enhanced Customer Satisfaction: Deliver products and services faster and more efficiently.

- Greater Agility: Adapt quickly to changing market conditions.

This listicle delivers practical advice, real-world examples, and clear implementation steps, making it a valuable resource for anyone seeking to improve operational efficiency.

1. Lean Manufacturing/Lean Six Sigma

Lean Manufacturing/Lean Six Sigma provides a systematic approach to improving operational efficiency by eliminating waste (muda) and streamlining processes. This methodology, initially developed for manufacturing, applies equally well to various business processes. It focuses on maximizing customer value while minimizing resource consumption. By optimizing workflow and reducing non-value-added activities, organizations can achieve significant improvements in productivity and profitability. The core principle of Lean Six Sigma is continuous improvement, fostering a culture of ongoing evaluation and optimization.

One of the key strengths of Lean Six Sigma is its data-driven approach. Through rigorous data analysis and statistical tools, organizations can pinpoint the root causes of inefficiencies and implement targeted solutions. Successful implementations have demonstrated dramatic results. Toyota, a pioneer of Lean, reduced defects by 90% and increased productivity by 40%. General Electric saved $12 billion over five years through Six Sigma, highlighting the potential for substantial cost savings.

Actionable Tips for Implementing Lean Six Sigma

To effectively implement Lean Six Sigma, consider the following tips:

- Start small: Begin with pilot projects to demonstrate value and gain buy-in before scaling across the organization.

- Invest in training: Equip your team with the necessary skills and knowledge through comprehensive Lean Six Sigma training.

- Visualize workflow: Implement visual management tools like Kanban boards to track progress and identify bottlenecks.

- Track and measure: Establish clear metrics and regular review cycles to monitor performance and ensure continuous improvement.

- Empower employees: Engage frontline workers in identifying improvement opportunities, leveraging their practical experience.

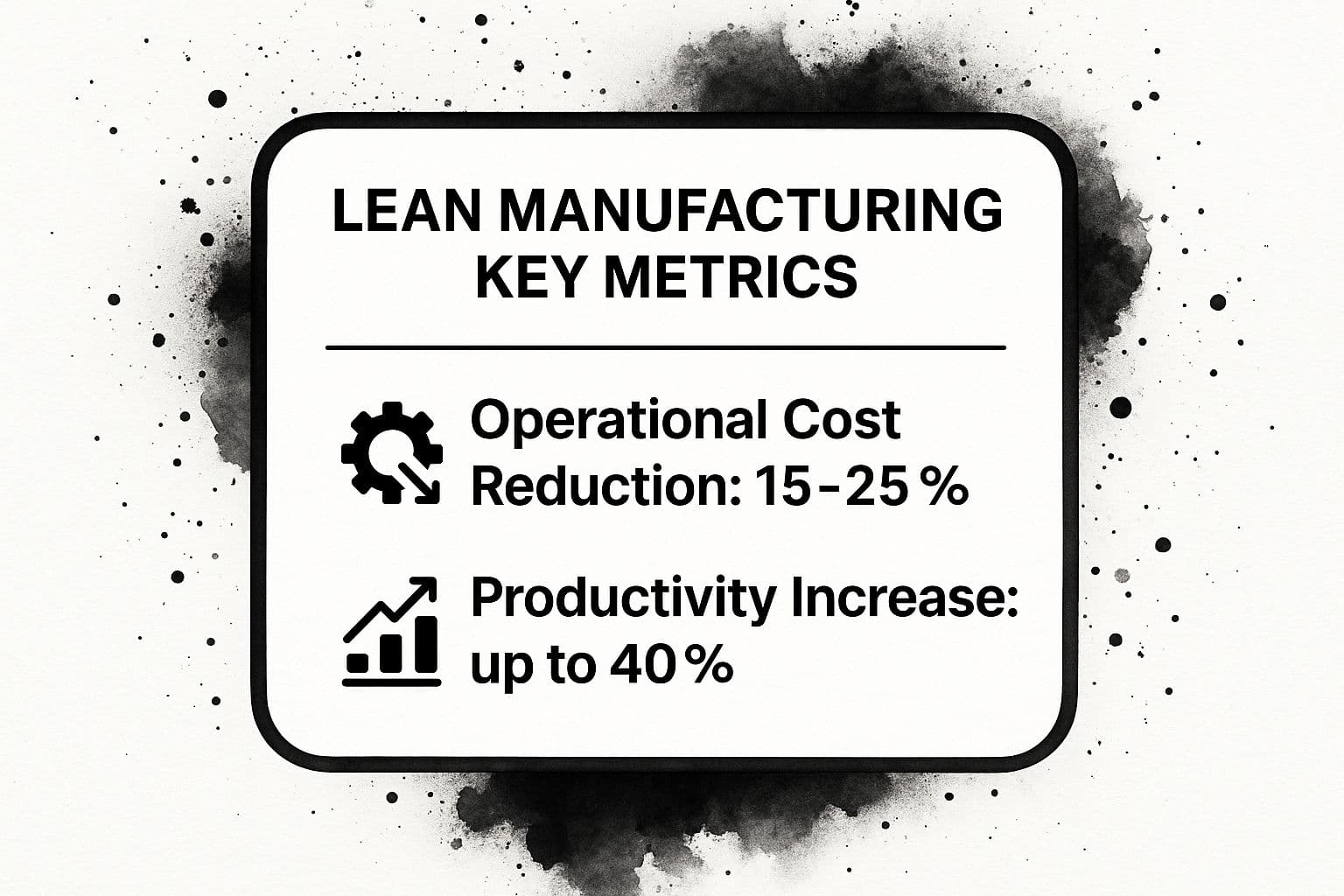

The following infographic visualizes key data points regarding cost reduction and productivity increases typically associated with Lean Six Sigma implementation.

As shown, organizations can anticipate an operational cost reduction of 15-25% and a productivity increase of up to 40% by adopting Lean Six Sigma principles. These improvements directly contribute to enhanced operational efficiency and a stronger bottom line. Lean Six Sigma offers a powerful framework for organizations seeking to improve operational efficiency, reduce costs, and enhance customer value. When striving for significant and sustainable process improvements, incorporating this proven methodology is highly beneficial.

2. Process Automation and Robotics

Process Automation and Robotics leverages technology, software, and robotics to execute repetitive tasks, minimize human error, and accelerate processing speed. This encompasses Robotic Process Automation (RPA), industrial robotics, and intelligent automation, which combines AI with traditional automation methods. By automating routine tasks, businesses can free up human capital for more strategic initiatives, leading to increased efficiency and improved operational outcomes. This approach allows organizations to optimize workflows and improve operational efficiency by reducing manual intervention and streamlining processes.

Companies like Amazon, JPMorgan Chase, Coca-Cola, and Deutsche Bank have successfully implemented process automation and robotics, demonstrating significant improvements in operational efficiency. Amazon's warehouse robots, for instance, have boosted efficiency by 20% and reduced operating expenses by the same margin. JPMorgan Chase's COIN program processes legal documents in seconds, completing work that previously required 360,000 lawyer hours. Coca-Cola automated invoice processing, reducing processing time from days to minutes. Similarly, Deutsche Bank automated trade settlements, achieving an 80% reduction in processing time.

Actionable Tips for Implementing Process Automation and Robotics

To successfully implement process automation and robotics, consider these tips:

- Start small: Begin with simple, rule-based processes to demonstrate value and gain experience.

- ROI Analysis: Conduct a thorough ROI analysis before implementing any automation solution.

- Change Management: Ensure proper change management and employee retraining to facilitate a smooth transition.

- Process Selection: Choose processes with high volume and low exception rates for maximum impact.

- Testing and Fallback: Implement robust testing and fallback procedures to mitigate potential risks.

Learn more about Process Automation and Robotics

Process automation and robotics offer a powerful approach to improve operational efficiency by streamlining workflows, reducing errors, and freeing up human resources. When facing challenges with repetitive tasks, high volumes of data processing, or error-prone manual processes, this methodology offers a solution to enhance productivity and drive substantial cost savings. Through automation, organizations can significantly improve operational efficiency and gain a competitive edge.

3. Enterprise Resource Planning (ERP) Implementation

Enterprise Resource Planning (ERP) systems offer a powerful solution for improving operational efficiency. These integrated software systems manage and integrate core business processes, including finance, HR, manufacturing, supply chain, and customer relationships. Modern ERP systems provide real-time data visibility and streamline operations across departments, fostering collaboration and informed decision-making. This integrated approach breaks down data silos, enabling a holistic view of the organization and facilitating better resource allocation.

Several companies have demonstrated significant success with ERP implementation. Hershey reduced inventory by $50 million and improved demand forecasting accuracy by 30% with SAP. Lenovo standardized processes across 60 countries, reducing operational costs by 15%. Colgate-Palmolive achieved $150 million in cost savings over five years through ERP standardization. Nike improved inventory turnover by 25% through integrated supply chain management. These examples highlight the potential of ERP for driving substantial improvements in various aspects of operational efficiency. For organizations looking to further optimize their processes, explore these field service automation tips.

Actionable Tips for Implementing ERP

To effectively implement ERP and improve operational efficiency, consider these tips:

- Conduct thorough business process mapping: Before implementation, understand your current processes to identify areas for improvement and ensure the ERP system aligns with your business needs.

- Invest in comprehensive user training and change management: Equip your team with the skills and knowledge to utilize the new system effectively and manage the transition smoothly.

- Start with core modules and expand gradually: Begin with essential modules and gradually incorporate additional functionalities to avoid overwhelming your team and ensure a successful rollout.

- Ensure strong executive sponsorship and project governance: Secure leadership support and establish clear project governance to maintain focus and accountability throughout the implementation process.

- Plan for data migration and system testing thoroughly: Ensure data integrity and system reliability by meticulously planning data migration and conducting rigorous testing before going live.

ERP systems offer a comprehensive approach to improve operational efficiency by streamlining processes, enhancing data visibility, and fostering collaboration across departments. By following these implementation tips, organizations can maximize the benefits of ERP and achieve significant improvements in productivity, cost savings, and overall business performance. When aiming to integrate disparate systems and centralize data for improved decision-making, ERP implementation is a highly valuable strategy.

4. Supply Chain Optimization

Supply chain optimization is a strategic approach to improving the flow of goods, information, and finances from supplier to customer. This involves optimizing inventory levels, reducing lead times, improving supplier relationships, and enhancing demand forecasting to minimize costs while maintaining service levels. Effective supply chain optimization boosts operational efficiency by streamlining processes and eliminating waste throughout the entire value chain.

Companies like Walmart, Zara, Dell, and Amazon have demonstrated the power of supply chain optimization. Walmart's cross-docking system significantly reduced inventory while improving product availability. Zara's fast fashion supply chain delivers new designs to stores much faster than the industry average. Dell's direct-to-customer model eliminated distributor costs and reduced inventory. Amazon's fulfillment network optimization drastically reduced delivery times. These examples highlight the potential for substantial improvements in efficiency and profitability.

Actionable Tips for Implementing Supply Chain Optimization

To effectively optimize your supply chain, consider these tips:

- Implement demand sensing technologies: Improve forecasting accuracy for better inventory management.

- Develop strategic partnerships: Collaborate with key suppliers for improved communication and reliability.

- Use supply chain mapping: Identify bottlenecks, risks, and opportunities for improvement.

- Invest in supply chain visibility platforms: Gain real-time insights into inventory levels and shipments.

- Regularly review transportation: Optimize routes and modes for cost and efficiency.

Supply chain optimization is crucial for any organization aiming to improve operational efficiency. By streamlining processes, reducing waste, and enhancing visibility, companies can achieve significant cost savings, improve customer satisfaction, and gain a competitive edge. This strategic approach is particularly beneficial for businesses with complex supply chains or those operating in volatile markets. Implementing these proven strategies can lead to a more resilient and efficient supply chain, directly contributing to improved operational efficiency and a healthier bottom line.

5. Data Analytics and Business Intelligence

Data Analytics and Business Intelligence (BI) provide a systematic approach to improving operational efficiency by leveraging the power of information. This methodology involves analyzing business data to identify patterns, trends, and insights that inform decision-making and process improvements. Modern analytics combines descriptive, predictive, and prescriptive analytics to optimize operations in real-time. By understanding past performance, predicting future outcomes, and prescribing optimal actions, organizations can achieve significant improvements in efficiency and profitability.

Successful implementations of data analytics and BI have demonstrated dramatic results. UPS's ORION system optimizes delivery routes, saving 100 million miles and $50 million annually. Effective supply chain optimization often involves careful Fleet Management. Netflix uses analytics to optimize content recommendations, increasing viewer engagement by 80%. GE's Predix platform for industrial IoT has prevented billions in equipment downtime. Starbucks uses location analytics to optimize store placement, improving success rates by 20%. These examples highlight the potential for data-driven insights to transform operations.

Actionable Tips for Implementing Data Analytics and BI

To effectively implement data analytics and BI to improve operational efficiency, consider these tips:

- Start with clear business questions: Define the specific problems you want to solve before collecting data.

- Invest in data quality: Implement data governance processes to ensure data accuracy and reliability.

- Train employees: Equip your team with the necessary data literacy and analytics tool skills.

- Focus on actionable insights: Prioritize insights that can be translated into concrete actions and process improvements.

- Implement a Center of Excellence: Create a dedicated team to drive analytics adoption and best practices across the organization.

Data analytics and BI offer a powerful framework for organizations seeking to improve operational efficiency, reduce costs, and enhance decision-making. When striving for significant and sustainable process improvements, incorporating this data-driven methodology is highly beneficial.

6. Agile and DevOps Methodologies

Agile and DevOps methodologies offer a dynamic approach to improve operational efficiency by emphasizing collaboration, continuous improvement, and rapid delivery. Originating in software development, these iterative principles now enhance various business functions, boosting responsiveness and efficiency. They prioritize flexibility and adaptation, enabling organizations to quickly respond to changing market demands and customer needs.

Agile focuses on iterative development cycles, frequent feedback, and close collaboration between cross-functional teams. DevOps extends this by integrating development and operations, automating processes, and accelerating deployment. Successful implementations demonstrate remarkable results. Spotify's squad model enabled rapid scaling while maintaining agility. ING Bank reorganized entirely around agile principles, reducing time-to-market by 20%.

Actionable Tips for Implementing Agile and DevOps

To effectively implement Agile and DevOps, consider these tips:

- Start with pilot teams: Gradually scale successful practices across the organization after initial testing.

- Invest in automation: Utilize automation tools and infrastructure to streamline processes.

- Focus on cultural transformation: Emphasize mindset shifts, not just process changes.

- Establish clear metrics: Track progress and ensure continuous improvement with defined metrics.

- Provide training and coaching: Support teams with extensive training and coaching.

Agile and DevOps offer a powerful framework to improve operational efficiency by fostering collaboration, accelerating delivery, and promoting continuous improvement. These methodologies empower organizations to adapt quickly, optimize workflows, and remain competitive in today's dynamic business environment. By embracing these principles, organizations can achieve significant improvements in productivity, time-to-market, and overall operational performance.

7. Continuous Improvement (Kaizen)

Continuous Improvement (Kaizen) is a philosophy and practice centered on making ongoing incremental improvements to operational processes. It involves all employees, from top-level management to frontline workers. Rather than seeking dramatic breakthroughs, Kaizen focuses on eliminating waste, improving productivity, and achieving sustained advancements over time. This creates a culture of continuous refinement, empowering every team member to contribute to enhancing efficiency.

Companies like Toyota, Lockheed Martin, Heineken, and Virginia Mason Medical Center have demonstrated Kaizen’s effectiveness. Toyota, a pioneer of the method, has implemented over 1 million Kaizen suggestions, contributing significantly to its world-renowned manufacturing excellence. Lockheed Martin reduced F-22 production time by 50% through continuous improvement initiatives. Heineken, focusing on sustainability, reduced energy consumption by 30% through employee-driven Kaizen events. Virginia Mason Medical Center, applying Kaizen to healthcare, reduced defects by an impressive 90%.

Actionable Tips for Implementing Continuous Improvement (Kaizen)

To effectively implement Kaizen within your organization, consider these practical tips:

- Establish suggestion systems: Implement easily accessible systems for employees to submit improvement ideas, ensuring rapid feedback and implementation.

- Recognize and reward contributions: Acknowledge and reward employees who contribute to improvement efforts, fostering a culture of engagement and ownership.

- Provide training: Invest in training programs that equip employees with problem-solving methodologies and tools for identifying and addressing inefficiencies.

- Focus on process: Prioritize process improvements over solely focusing on cost reduction; enhanced processes naturally lead to reduced costs and increased efficiency.

- Create cross-functional teams: Assemble teams with members from different departments to address process challenges from multiple perspectives and foster collaboration.

Learn more about Continuous Improvement (Kaizen)

By adopting a Kaizen mindset, organizations can build a culture of continuous improvement that promotes long-term efficiency and sustainability. These incremental enhancements, compounded over time, yield substantial gains in productivity, quality, and overall operational effectiveness. When striving to improve operational efficiency by consistently optimizing processes, Kaizen proves to be a powerful methodology.

8. Outsourcing and Offshoring Strategic Functions

Outsourcing and offshoring strategic functions involves delegating non-core business activities to external service providers. Outsourcing refers to domestic providers, while offshoring involves international partners. This approach offers significant potential to improve operational efficiency by reducing costs, accessing specialized expertise, and freeing internal resources to focus on core competencies. By strategically leveraging external capabilities, organizations can streamline operations and enhance their competitive advantage.

Companies across various industries have successfully implemented outsourcing and offshoring to achieve substantial operational improvements. IBM saved $4 billion annually by outsourcing IT infrastructure services. General Electric's "GE Capital" outsourced back-office operations to India, saving 40% on operational costs. Alibaba outsources customer service, handling over 500 million customer interactions. Netflix outsources content moderation and customer support to prioritize content creation and technological advancements. These examples demonstrate the potential for cost savings and improved efficiency through strategic delegation.

Actionable Tips for Implementing Outsourcing and Offshoring

To effectively implement outsourcing and offshoring, consider these key tips:

- Clearly define service level agreements (SLAs) and performance metrics: Establish clear expectations and measurable outcomes to ensure accountability and performance.

- Choose partners based on capabilities, not just cost: Evaluate potential providers based on their expertise, experience, and track record, rather than solely focusing on price.

- Maintain strong governance and oversight processes: Implement robust monitoring mechanisms to track performance, manage risks, and ensure compliance.

- Develop robust communication and collaboration frameworks: Establish clear communication channels and collaborative processes to facilitate seamless interaction and knowledge sharing.

- Plan for knowledge transfer and change management: Address potential knowledge gaps and manage the transition effectively to minimize disruption and ensure a smooth handover.

Outsourcing and offshoring offer a powerful means to improve operational efficiency when implemented strategically. By carefully selecting partners, establishing clear agreements, and maintaining strong oversight, organizations can leverage external expertise to optimize processes, reduce costs, and focus on core business functions that drive growth and innovation. This approach allows companies to adapt to changing market demands and enhance their overall competitiveness.

9. Workflow Standardization and Documentation

Workflow standardization and documentation involves systematically defining and documenting business processes to ensure consistency, reduce variability, and enable continuous improvement. This includes creating standard operating procedures (SOPs), process maps, and training materials. By clearly outlining each step of a process, organizations can minimize errors, improve communication, and enhance overall operational efficiency. Standardization allows employees to perform tasks consistently, regardless of experience level, leading to predictable and reliable outcomes.

Companies like McDonald's, Southwest Airlines, and the Mayo Clinic have achieved significant operational improvements through workflow standardization. McDonald's standardized operations manual, for example, enabled global franchise consistency and rapid expansion. Southwest Airlines’ standardized maintenance procedures contributed to reduced aircraft turnaround time. These examples showcase how standardized processes can drive efficiency and improve performance.

Actionable Tips for Implementing Workflow Standardization and Documentation

To effectively implement workflow standardization and documentation, consider these tips:

- Involve frontline employees: Leverage their practical experience to create accurate and user-friendly documentation.

- Use visual aids: Flowcharts and diagrams can enhance clarity and understanding of complex processes.

- Regular review and update: Ensure procedures remain relevant and reflect best practices by incorporating feedback and adapting to changes.

- Implement version control: Track changes and maintain a clear history of document revisions.

- Balance standardization with flexibility: Allow for exceptions and deviations when necessary to accommodate unique situations.

Workflow standardization and documentation offer a powerful approach to improve operational efficiency by reducing errors, improving communication, and ensuring consistency. When striving for predictable processes and sustainable performance enhancements, adopting this methodology provides a strong foundation for continuous improvement and streamlined operations.

10. Performance Management and KPI Optimization

Performance Management and KPI Optimization provides a systematic approach to measuring, monitoring, and improving organizational performance. This is achieved through Key Performance Indicators (KPIs), balanced scorecards, and performance management systems that align individual and team performance with strategic objectives. By establishing clear, measurable goals and tracking progress against them, organizations can identify areas for improvement and drive better results. This data-driven approach allows for objective assessment and informed decision-making, fostering a culture of continuous improvement and accountability.

Companies like Google, with its OKR (Objectives and Key Results) system, have seen significant improvements in goal alignment and achievement rates. Salesforce's V2MOM framework (Vision, Values, Methods, Obstacles, Measures) has been credited with contributing to their 30x revenue growth. While General Electric's forced ranking system initially drove performance improvements, it was later abandoned due to its negative impact on company culture, highlighting the importance of balancing performance measurement with employee well-being. To further enhance organization and efficiency, consider adopting effective workflow management systems.

Actionable Tips for Implementing Performance Management and KPI Optimization

To effectively implement Performance Management and KPI Optimization, consider these tips:

- Focus on leading indicators: Don't just track lagging metrics. Look at predictive measures that can anticipate future performance.

- Ensure KPIs are SMART: KPIs should be Specific, Measurable, Achievable, Relevant, and Time-bound.

- Regular review and adjustment: Performance metrics should be reviewed and adjusted regularly to ensure they remain aligned with business goals.

- Balance individual and team performance: Strike a balance between individual accountability and collaborative team efforts.

- Provide training: Invest in training on performance management best practices to ensure everyone understands the system and its purpose.

Performance Management and KPI Optimization offers a powerful framework for organizations seeking to improve operational efficiency. By aligning individual and team efforts with strategic objectives and providing a clear, data-driven approach to performance improvement, this methodology empowers organizations to achieve sustainable growth and success. It offers a practical and effective way to translate strategic goals into tangible results.

Operational Efficiency Strategies Comparison

| Item | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Lean Manufacturing/Lean Six Sigma | High – cultural change + ongoing training | Moderate to high – training & tools | Operational cost ↓ 15-25%, productivity ↑ 40% | Manufacturing, process optimization, waste reduction | Waste elimination, continuous improvement |

| Process Automation & Robotics | High – technical expertise, integration | High – investment in technology | Labor cost ↓ 25-50%, speed ↑ 3-5x | Repetitive, high-volume tasks, data entry, invoicing | Error elimination, 24/7 operation |

| ERP Implementation | Very High – long timelines, process reengineering | Very High – software, consulting, training | Operational cost ↓ 10-20%, data visibility ↑ | Enterprise-wide process integration | Data unification, real-time analytics |

| Supply Chain Optimization | High – complex global coordination | Moderate to high – tech & supplier collaboration | Inventory cost ↓ 20-30%, customer service ↑ | End-to-end logistics, demand forecasting | Risk reduction, improved agility |

| Data Analytics & Business Intelligence | High – tech, talent, data quality focus | High – analytics platforms and skills | Decision speed & accuracy ↑, cost optimization | Data-driven decision making, predictive insights | Competitive advantage through insights |

| Agile and DevOps Methodologies | Moderate to High – cultural and process change | Moderate – automation tools & training | Time-to-market ↓ 50-70%, product quality ↑ | Software dev, rapid delivery, continuous improvement | Faster delivery, improved collaboration |

| Continuous Improvement (Kaizen) | Low to Moderate – cultural buy-in needed | Low to Moderate – employee involvement | Productivity ↑ 3-5% annually, defects ↓ 50-80% | Incremental process improvements, employee engagement | Low cost, sustainable long-term gains |

| Outsourcing & Offshoring | Moderate – partner management complexity | Moderate – vendor & contract management | Operational costs ↓ 20-40% | Non-core functions, cost reduction, expertise access | Cost savings, access to global talent |

| Workflow Standardization & Documentation | Moderate – documentation and maintenance | Low to Moderate – process teams & tools | Errors ↓, onboarding speed ↑, compliance ↑ | Quality control, regulatory environments | Consistency, error reduction |

| Performance Management & KPI Optimization | Moderate – requires cultural alignment | Moderate – software & analysis time | Performance alignment, accountability ↑ | Goal tracking, employee motivation | Data-driven performance improvement |

Sustaining Operational Excellence: A Continuous Journey

Improving operational efficiency is not a destination but an ongoing journey of refinement and adaptation. This listicle has explored ten key strategies, from leveraging lean principles and automation to harnessing the power of data analytics and agile methodologies, all of which contribute to a more streamlined and effective organization. By implementing these strategies, businesses can unlock significant improvements in productivity, reduce costs, and enhance overall performance.

Key Takeaways for Lasting Impact

The most impactful takeaways from this collection center around the importance of continuous improvement, data-driven decision-making, and embracing change. Whether you're optimizing your supply chain, implementing an ERP system, or standardizing workflows, the commitment to ongoing evaluation and refinement is paramount. Regularly assessing your processes against key performance indicators (KPIs) ensures you stay on track and adapt to evolving market demands. Remember that operational efficiency isn't just about speed; it's about delivering value effectively and maximizing your organization's potential.

Next Steps to Improve Operational Efficiency

To truly embed these concepts into your organization, consider the following next steps:

- Prioritize: Select one or two strategies that align with your immediate needs and resources.

- Pilot: Implement your chosen strategy on a smaller scale before full-scale deployment. This allows for controlled testing and refinement.

- Measure: Track your progress with clearly defined KPIs. Data-driven insights are essential for ongoing optimization.

- Adapt: Be prepared to adjust your approach based on the data and feedback you gather. The business landscape is constantly evolving, so your operational strategies must evolve too.

The Future of Efficiency: Embracing Adaptability

In the fast-paced world of 2025 and beyond, agility and adaptability are key to survival. By embracing the strategies outlined in this article and committing to a culture of continuous improvement, you can navigate the complexities of the modern business environment and achieve sustainable growth. Improving operational efficiency is an investment in your organization's future, enabling you to not only meet current challenges but also thrive in the face of future opportunities.

Ready to streamline your operations and unlock your organization's full potential? Fluidwave offers a comprehensive suite of tools designed to improve operational efficiency, from project management and workflow automation to data analytics and reporting. Visit Fluidwave to learn more and discover how Fluidwave can empower your team to achieve operational excellence.

Focus on What Matters.

Experience lightning-fast task management with AI-powered workflows. Our automation helps busy professionals save 4+ hours weekly.