Learn what is operational efficiency and discover key strategies to improve processes, reduce costs, and increase productivity now.

September 14, 2025 (5mo ago)

What Is Operational Efficiency? Boost Your Business Today

Learn what is operational efficiency and discover key strategies to improve processes, reduce costs, and increase productivity now.

← Back to blog

At its core, operational efficiency is all about getting the absolute most out of what you put in. It’s the practice of delivering your products or services in the most cost-effective and time-effective** way imaginable, without letting quality slip.

Understanding Operational Efficiency Beyond the Buzzword

Think of operational efficiency as the engine powering your business. It's not just a fancy term for cutting costs; it's about building smarter, more resilient systems that give you a real competitive edge.

When an operation is truly efficient, waste is eliminated, friction is reduced, and your team is freed up to focus on work that actually moves the needle. Workflows are smooth, resources are used wisely, and every action has a clear, strategic purpose.

This isn't a new concept, of course. For decades, companies have been chasing efficiency through new technologies and process innovations. You can find more insights on the latest trends at sdocs.com.

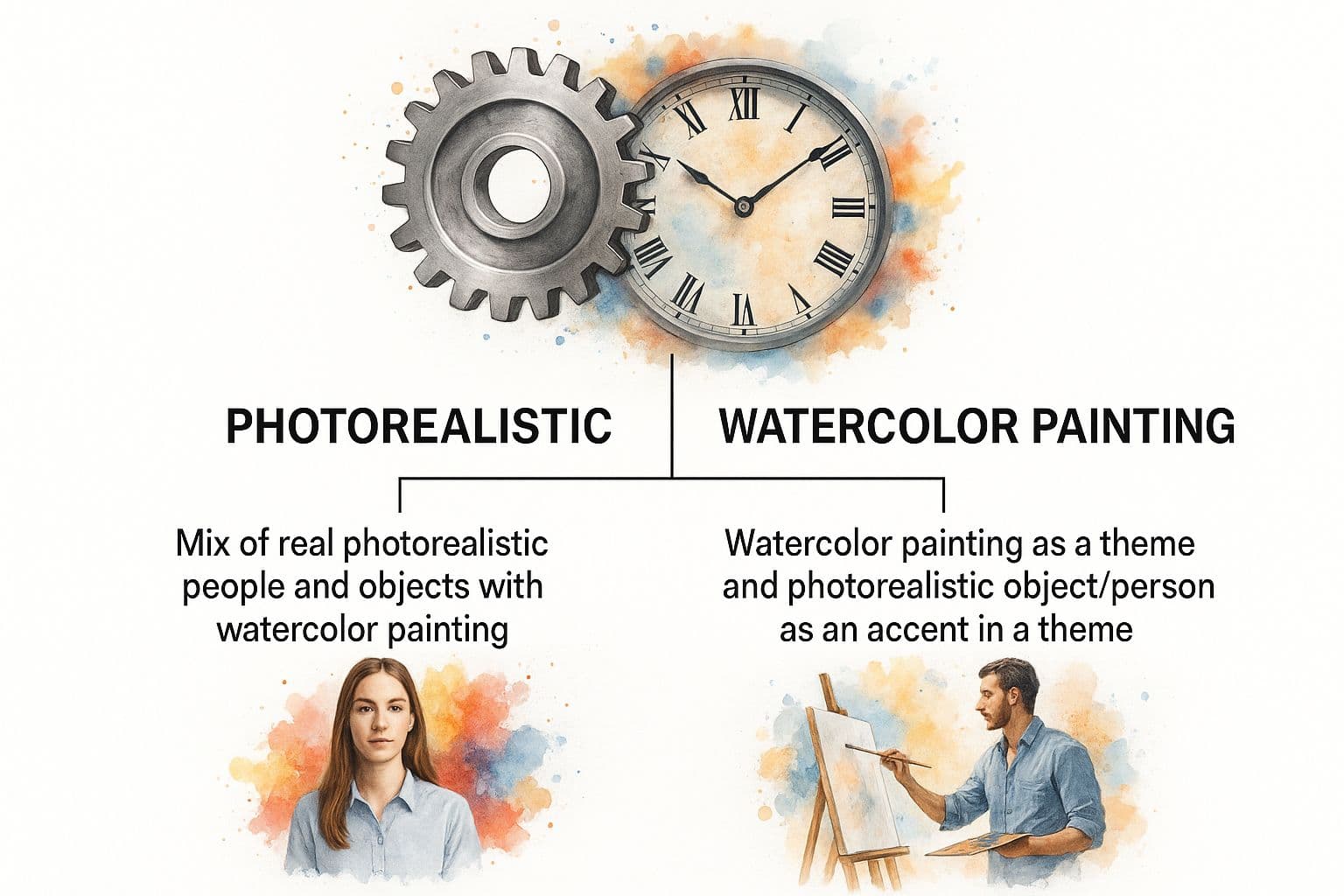

The image below gives a great visual of how crucial elements like time, resources, and processes all have to work together.

As you can see, efficiency is a dynamic system. How you manage time directly impacts how you use your resources, which in turn affects the outcome of your processes. It's all connected.

The Core Pillars of Operational Efficiency

So, what does this look like day-to-day? To really get a handle on operational efficiency, it helps to break it down into its core pillars. These are the key areas that, when working in concert, create a truly seamless and productive operation.

The table below summarizes these foundational concepts at a glance.

| Pillar | What It Means | Real-World Example |

|---|---|---|

| Process Optimization | Constantly refining workflows to cut out unnecessary steps, bottlenecks, and delays that slow things down. | A software team using automation to handle repetitive code testing, freeing up developers to focus on new features. |

| Resource Management | Getting the most out of every asset you have—from your team's skills and your technology stack to your budget. | A manufacturing plant scheduling machine maintenance during off-peak hours to avoid disrupting production. |

| Quality Control | Building quality checks into the process from the start, not just catching mistakes at the end. | A call center monitoring calls in real-time to provide immediate feedback and training to agents. |

These pillars aren't just separate tasks; they support each other to build a strong foundation for a high-performing business.

At its heart, operational efficiency is about creating more value with less effort. It's the difference between a team that is merely busy and one that is genuinely productive, driving tangible results for the business.

To see how these principles come to life in a real-world framework, it’s worth exploring what DevOps methodology entails, as it’s a perfect example of these ideas in action.

Why Efficient Operations Are Your Greatest Advantage

It’s one thing to talk about operational efficiency in theory, but what does it actually look like in the real world? It's the difference between a business that’s just getting by and one that's built to last.

Picture two companies selling the exact same product. Company A is a mess of bottlenecks. Teams are walled off from each other, rework is a daily headache, and simple customer requests disappear into a black hole of bureaucracy. Meanwhile, Company B has made efficiency its mantra. Their processes are clean, they automate the tedious stuff, and information flows freely.

Which one do you think comes out on top?

The Tangible Rewards of Efficiency

The goal is to become Company B, and the rewards aren't just feel-good concepts—they hit the bottom line. When you get serious about running a tight ship, you start building advantages that competitors can't easily copy.

These benefits ripple through every corner of your business:

- Skyrocketing Profitability: It's simple, really. When you cut out the waste and lower the cost of doing business, every sale you make is more profitable. A study from J.P. Morgan Chase found that clients of highly efficient firms saw their fund operating costs plummet by 39%. That’s a massive competitive edge.

- Enhanced Customer Satisfaction: Smooth internal operations lead to a better customer experience. Think faster response times, quicker delivery, and fewer mistakes. Happy customers don't just come back; they become your best salespeople.

- Empowered and Engaged Employees: Nobody enjoys wrestling with clunky software or hunting for information that should be easy to find. When you streamline workflows and automate repetitive tasks, your team can focus on the meaningful work they were hired to do. This isn't just good for morale; it's great for retention.

Operational efficiency is your ultimate competitive moat. Competitors can copy your products or your marketing campaigns, but they can't easily replicate a deep-seated culture of seamless, waste-free execution.

In the end, this commitment to excellence makes your entire business more resilient. Instead of constantly putting out internal fires, you can channel that energy into what really matters: innovating and growing. That’s how operational efficiency becomes your single greatest advantage.

How to Measure What Truly Matters in Your Operations

There’s an old saying in business: you can’t improve what you don’t measure. To get a real handle on operational efficiency, you need clear metrics. Think of them as diagnostic tools that reveal your company’s strengths and, just as importantly, its hidden weaknesses.

These key performance indicators (KPIs) let you move beyond gut feelings and start using hard data to steer the ship. They help you pinpoint the exact source of a bottleneck, set realistic goals for improvement, and actually see if your changes are working over time.

For a closer look at the specific formulas and tracking methods, our guide on how to measure operational efficiency is a great resource.

Essential Metrics for Operational Health

Every business is different, but a handful of core metrics can give you a powerful snapshot of your performance. Consider these the vital signs for your company's processes.

-

Process Cycle Time: This is the total time it takes to get something done from start to finish. How long does it take from the moment a customer places an order until that box is on a truck? Long cycle times are a huge red flag for delays and unnecessary steps.

-

Throughput: This metric is all about output rate. It answers the simple question, "How much can we get done in a set period?" A factory might measure units produced per hour, while a customer service team could track tickets resolved per day.

-

Resource Utilization: This one tells you how effectively you're using your assets—whether that’s machinery, software licenses, or your team’s valuable time. While high utilization sounds great, pushing for 100% utilization is often a mistake. It leaves no room for unexpected problems and can quickly lead to team burnout.

By keeping a close eye on these metrics, you turn vague goals into concrete numbers. You can see precisely if your adjustments are making a difference, which is the foundation for a culture of continuous, data-driven improvement.

A Broader Economic Perspective

Operational efficiency isn't just a concern for individual businesses; it’s tracked on a national scale, too. Labor productivity, for example, measures economic output per hour worked across an entire country.

In 2023, labor productivity across OECD countries grew by a modest 0.6%. The United States, on the other hand, posted a more promising 1.6% increase, hinting at a return to pre-pandemic efficiency levels. You can dig into these global productivity trends from the OECD for a bigger picture.

Actionable Strategies to Drive Operational Improvement

Knowing your metrics is just the starting line. The real race is won by turning that data into meaningful, real-world progress. Improving operational efficiency isn’t about just working harder; it’s about architecting smarter systems that remove friction and let your team do their best work.

The challenge is to move from theory to action. This means pinpointing the exact sources of waste and opportunity in your workflows and then applying proven strategies to fix them. Let’s dive into some of the most effective methods you can put into practice right away.

Automate Repetitive and Low-Value Tasks

Every business is bogged down by them: the tedious, manual jobs that eat up time and energy but contribute little strategic value. We’re talking about things like data entry, pulling standard reports, or sending out reminder emails. These are perfect candidates for automation.

Handing these routine jobs over to technology not only speeds things up but also drastically cuts down on human error. A marketing team, for example, could automate its social media scheduling. This simple change frees up hours each week while guaranteeing a consistent presence online.

Automation isn't about replacing people—it's about elevating them. It takes the robotic work off their plate so they can focus on the creative problem-solving and strategic thinking that actually moves the needle.

Adopt Lean Principles to Eliminate Waste

The lean methodology, which has its roots in manufacturing, is a brilliant framework for identifying and cutting out anything that doesn't add value for your customer. It shines a spotlight on the common sources of operational drag that often hide in plain sight. To get started, you just need to know what to look for.

Key areas of waste to target include:

- Waiting: All that dead time spent waiting for the next step, like an approval or information from another team.

- Over-processing: Doing more work than is actually needed, such as creating exhaustive reports that nobody reads.

- Defects: Errors that force you to do the work all over again, burning time and money to fix problems that were preventable.

By methodically hunting down and removing these inefficiencies, you can build a much smoother, faster, and more cost-effective operation. For a deeper dive, check out a comprehensive war plan for improving operational efficiency.

Standardize Your Key Workflows

Inconsistency is a quiet killer of efficiency. When everyone on the team has their own unique way of handling a common task, it’s impossible to measure performance, pinpoint what works best, or train new people effectively. Standardizing your core processes is the answer.

This means creating a single, documented, and agreed-upon method for handling repetitive tasks. It could be a simple checklist for onboarding a new client or a template for project kickoff meetings. Standardization breeds predictability, slashes mistakes, and makes it far easier to spot opportunities for the next round of improvements. To learn more, check out our guide on how to streamline business processes.

Balancing Technology and Talent for Peak Performance

So, what’s the real secret to boosting operational efficiency? Is it better software or a more skilled team? The truth is, it's never an either-or question. The most effective organizations understand that technology and talent are two sides of the same coin. Peak performance is found where they meet.

Think of modern tools like AI and automation not as replacements for your people, but as powerful partners. Their real value shines when they take over the tedious, repetitive tasks, freeing up your team to focus on what humans do best: complex problem-solving, creative strategy, and nurturing client relationships.

But here’s the catch: even the most sophisticated software will gather dust if it’s dropped into a culture that resists change or lacks the skills to make it work. This is where the human element is non-negotiable.

Cultivating a Culture of Continuous Improvement

Technology gives you the tools, but it’s your team that provides the ingenuity and the drive to use them well. An empowered workforce doesn't just use new software; they actively look for ways to make the entire system smarter and more efficient.

To get there, you need to foster a very specific mindset.

- Invest in Upskilling: Don't just hand over new tech. Provide ongoing training to build confidence and competence so your team can master the tools you give them.

- Encourage Feedback: Create open channels for employees to point out process bottlenecks and suggest smarter ways of working. They're on the front lines and see things you don't.

- Celebrate Innovation: When a team member discovers a more efficient workflow, celebrate it. Recognizing and rewarding this initiative encourages everyone to think like an innovator.

The goal is to create an environment where technology serves the team, not the other way around. Our guide to AI-powered workflow automation dives deeper into how these tools can support and elevate your people.

The most significant gains in operational efficiency come when an engaged, skilled workforce is equipped with technology that amplifies their intelligence and frees up their time.

Ignoring the human factor comes with a staggering price tag. While the global market for productivity software reached nearly $60 billion in 2023, disengaged employees cost the global economy an estimated $8.9 trillion in lost GDP. As you can see from these productivity statistics from MyHours.com, tools alone are never the complete answer.

Wrapping It Up: Your Path Forward

Think of achieving operational excellence less like a project with a finish line and more like a mindset. It's a continuous journey, a marathon, not a sprint. The goal isn't to flip a switch and become perfectly efficient overnight; it's about embedding a culture of constant, thoughtful improvement into the very fabric of your business.

We've walked through what operational efficiency really means, how to measure it, and the strategies you can put into practice. Now it's your turn to apply these ideas. The key is to start small. Don't try to boil the ocean or fix everything at once. Just pick one thing—that one process that always feels clunky or that bottleneck everyone complains about.

The real magic happens when you build momentum. Tackle one problem, measure the improvement, and let that success energize your team for the next challenge.

You're now equipped with a solid framework for building a smarter, more resilient operation. The journey doesn't begin with a massive, disruptive overhaul. It starts with a single, deliberate step in the right direction. Take that step today.

Frequently Asked Questions

When you start digging into operational efficiency, a few common questions always seem to pop up. Let's clear up some of the most frequent ones so you can move from just thinking about efficiency to actually making it happen in your business.

Operational Efficiency vs. Productivity

It's easy to mix these two up, but they're not the same thing. Think of it this way: Productivity is about how much you get done. It's a simple measure of output versus input, like how many sales calls a rep makes in a day.

Operational efficiency, on the other hand, is about how well you get it done. It looks at the bigger picture—the entire system—to find and eliminate wasted time, money, and effort. You can have an incredibly productive team that's burning themselves out working within a broken, inefficient process. Efficiency is about making the whole engine run smoother, not just revving one part of it.

How Can I Improve Efficiency on a Small Budget?

You don't need a huge war chest to make a real difference. In fact, some of the most powerful improvements cost next to nothing. The trick is to find the small hinges that swing big doors.

- Get visual with your process: Grab a whiteboard or even just a piece of paper and map out a workflow from start to finish. You’ll be amazed at how quickly the obvious bottlenecks and silly, redundant steps jump out at you.

- Go talk to your team: Your frontline employees are a goldmine of information. They live with the friction and frustrations every single day, and they often have brilliant, simple ideas for how to fix them. Just ask.

- Start with simple tools: You don't need a massive software overhaul. Free or affordable project management tools can work wonders for clarity. Even something as basic as a standardized checklist for a common task can slash errors and boost quality.

The secret to getting started is to resist the urge to fix everything at once. Pick one frustrating, time-sucking process and focus all your effort there. Make one small, smart change, see what happens, and build on that success. That's how you create real, lasting momentum.

Ready to stop wrestling with bottlenecks and start automating your workflows? Fluidwave blends AI-powered task management with expert human virtual assistants to help you get more done with less effort. Start streamlining your operations today at fluidwave.com.

Focus on What Matters.

Experience lightning-fast task management with AI-powered workflows. Our automation helps busy professionals save 4+ hours weekly.